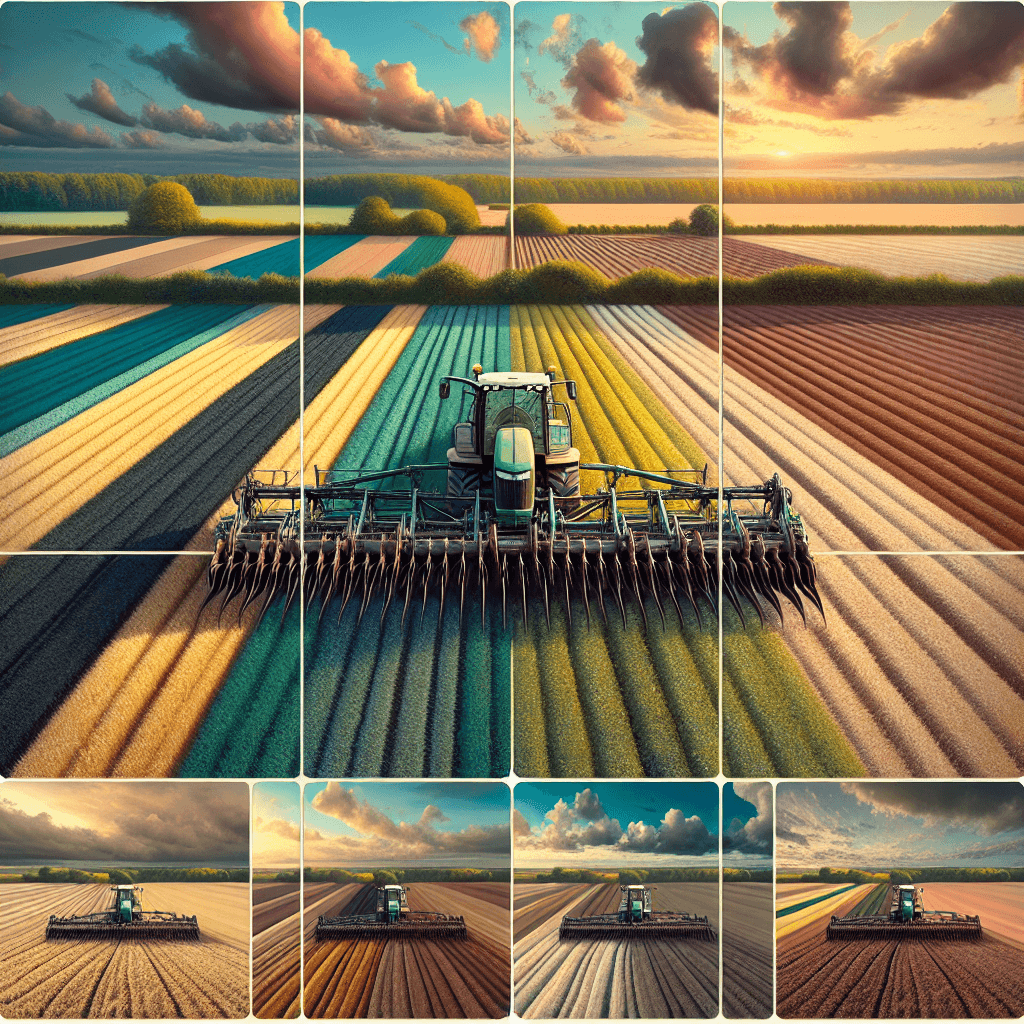

Keeping farm machinery in prime condition is vital for maximizing productivity and ensuring a smooth and efficient farming operation. One often overlooked but crucial component in soil preparation and equipment maintenance is the disk blade scraper. These handy tools prevent soil buildup on disk blades, ensuring your tillage processes run effortlessly and maintaining the longevity of your equipment. For farmers in Ipswich, locating the best disk blade scrapers isn’t just about convenience; it’s about acquiring reliable, long-lasting tools that enhance performance and durability. Let’s dive into why investing in top-quality disk blade scrapers is essential for achieving peak farm performance.

Exploring the Qualities of a Superior Disk Blade Scraper

In the realm of farming, especially in places like Ipswich where soil conditions can vary greatly, ensuring that your equipment performs optimally is crucial. One often overlooked component, yet essential, is the disk blade scraper. Understanding what makes a quality disk blade scraper and how it contributes to the overall efficiency of your farming operations can not only boost productivity but also extend the life of your machinery.

The Essential Role of Disk Blade Scrapers

Disk blade scrapers are pivotal in maintaining the performance of your agricultural equipment, playing a key role in preventing soil buildup on the discs. This buildup, if not adequately managed, can hinder smooth operation and effective tillage. By keeping the disk blades clear of mud and debris, scrapers ensure consistent soil penetration and help prevent blockages that could otherwise reduce efficiency. Moreover, they significantly contribute to the longevity and effectiveness of your agricultural implements, a crucial consideration for farmers wanting to make the most of their investments.

Identifying Key Features

When searching for the best disk blade scraper, specific features stand out as indicators of quality. First, material quality is paramount. A scraper made from durable materials with high resistance to wear can withstand harsh conditions, common in Ipswich’s varied fields. It’s also essential for the scraper to be compatible with different types of disk blades—whether notched, smooth, or wavy—since each has unique maintenance demands. Ease of installation and adjustment across various equipment types is another feature that should not be overlooked, as it can save time and reduce equipment downtime.

The Impact of Different Disk Blade Types

Disk blades come in various forms, each impacting the choice of scraper. Smooth blades, for instance, might require scrapers that can handle fine particles to prevent rapid buildup, while notched and wavy blades might demand sturdy scrapers to deal with heavier residues. Choosing the right disk blade scraper in Ipswich means considering both the blade type and the local soil conditions—another reason why understanding your equipment is crucial.

Selecting a high-quality disk blade scraper is not just about immediate benefits such as smooth operation and efficient tillage but also about the long-term impacts, including less equipment wear and tear. As a farmer in Ipswich, investing time to understand these components means committing to increased productivity and prolonged equipment life. Seek out those local experts and resources available who can guide you in making informed decisions tailored to the specific needs of your farm. With the right insights and tools, farmers can ensure that their operations are as efficient and productive as they can be.

What Makes a Quality Disk Blade Scraper?

Understanding Disk Blade Scraper Functions

Disk blade scrapers may seem like small components, but they are a fundamental part of agricultural machinery. They play a crucial role by preventing soil buildup on the disks, which could otherwise lead to ineffective tillage operations. Envision trying to run a marathon with sticky mud clinging to your shoes — you’d waste energy and gain little ground. That’s precisely what these scrapers prevent for your equipment. By keeping the disk blades clean and operational, they ensure smooth soil penetration and maintain efficient tillage. Additionally, they contribute significantly to the longevity of the machine, effectively reducing wear and tear over time.

Key Features to Look For

Quality disk blade scrapers have several features that set them apart. First and foremost is the material quality. Opt for those made from high-grade, wear-resistant materials. These scrapers withstand the rigorous demands of farming, reducing your need to frequently replace them. Another key aspect is the compatibility with various blade types, whether they are notched, smooth, or wavy. Having a scraper that can adapt means you’re prepared for different challenges and soil conditions. Finally, ease of installation and adjustment should not be overlooked; you want a scraper that can fit snugly onto multiple equipment types with minimal hassle.

Types of Disk Blades and Their Impact

Each type of disk blade presents its own challenges and maintenance needs. Smooth blades, while excellent for general use, can quickly get clogged in sticky soil. Notched blades, with their aggressive cutting action, require a scraper that can handle more debris without wearing down. Wavy blades, on the other hand, are designed for residue-heavy fields, necessitating a scraper that can clear large amounts of debris efficiently. The key is to match the right scraper with the blade type and the specific soil conditions you face around Ipswich. This alignment ensures optimal field performance and equipment longevity.

Investing in the right disk blade scraper, particularly one suited to your Ipswich farm conditions, is an investment in your equipment’s effectiveness and durability. By considering the features, materials, and compatibility with your specific disk blades, you ensure that your agricultural implements are always operating at peak performance. Above all, a well-chosen disk blade scraper means fewer interruptions during vital farming operations and, ultimately, a more successful harvest each season. Remember, the perfect scraper is one that becomes an integral part of your routine, making fieldwork smoother and more efficient.

Conclusion

The significance of keeping farm machinery in optimal condition cannot be overstated for farmers striving for maximum productivity. Disk blade scrapers stand out as essential components for effective soil preparation, directly impacting the operational efficiency and longevity of agricultural equipment. Finding the best disk blade scrapers in Ipswich is crucial, providing local farmers with reliable and durable tools that enhance performance.

Understanding the role and functionality of disk blade scrapers is vital. They prevent soil buildup on discs, ensuring smooth operation and extended lifespan of agricultural tools. Quality scrapers boast superior material resistance, compatibility with various blade types, and ease of installation and adjustment—key features that demand attention when making a selection.

Choosing an appropriate disk blade scraper involves assessing your equipment and specific field conditions, factoring in local soil types and residue levels. Local sourcing offers benefits such as quick access and after-sales support, making Ipswich-based suppliers an attractive option. Performance, durability, warranty, and parts availability should guide your comparison of potential scrapers.

Proper maintenance enhances scraper efficiency and lifespan. Routine cleaning, inspection, lubrication, and mindful storage practices are imperative. Being alert to signs of wear ensures timely replacement, preventing disruptions in farm operations.

In essence, a wise investment in the right disk blade scraper translates into superior soil preparation, reduced equipment wear, and ultimately, higher yields. Taking proactive steps as outlined ensures improved productivity and substantial long-term savings for farmers, reinforcing the importance of meticulous equipment management in achieving peak farm performance.

Types of Disk Blades and Their Impact

When it comes to selecting the perfect disk blade scraper for your Ipswich farm, understanding the types of disk blades and their specific maintenance needs is crucial. Different blade designs can dramatically affect your equipment’s efficiency, and the right scraper choice can make all the difference in maintaining performance and reducing downtime.

Smooth, Notched, and Wavy Blades

Let’s start by exploring the three primary types of disk blades: smooth, notched, and wavy. Each of these designs serves distinct purposes and requires tailored scrapers.

- Smooth Blades: These are ideal for lighter soils with minimal residue. They offer excellent surface penetration but can struggle with soil buildup, making scrapers essential for keeping them clean and effective throughout their operation.

- Notched Blades: Featuring sharp, serrated edges, notched blades handle tougher soils and more residue. Proper scraper contact ensures these blades remain free of debris, allowing for continuous cutting efficiency.

- Wavy Blades: Designed for fine chopping and residue mixing, wavy blades are relied upon in conservation tillage. Their undulating design can trap soil easily, making the right scraper pairing vital for their functionality.

Blade Type and Soil Conditions

Choosing the right scraper doesn’t just depend on your blade type; it’s also crucial to consider your local soil conditions in Ipswich. Here’s why:

- Sandy and Light Soils: Sandy soils are less likely to clump, which means smooth blades paired with less aggressive scrapers will usually suffice. However, vigilance is required to ensure minimal residue remains.

- Clay Soils: These can be stickier and more difficult to manage. Notched or wavy blades with sturdy scrapers can offer the extra cleaning power needed to prevent clogs.

- Rocky Terrain: Such conditions demand robust scrapers that can handle impact and resist wear, maintaining blade efficiency without additional downtime.

Choosing the Right Scraper

Given these distinctive challenges, finding the right disk blade scraper in Ipswich tailored to your specific blade type and soil condition is paramount. Not only does it guarantee smooth operations, but it also ensures equipment longevity, saving you time and money in the long run.

Integrating the best scrapers for your blades fosters better soil preparation and enhances productivity. So, whether you’re battling clay or light soils, investing in high-quality, compatible scrapers is a surefire way to peak farm performance.

FAQs

What is the main function of a disk blade scraper?

A disk blade scraper keeps the surface of the disk blades clear of mud and debris, ensuring consistent soil penetration and preventing blockages that can reduce the efficiency of tillage operations.

How often should I inspect or replace my disk blade scraper?

Regular inspections should be done before and after every use. Replacement is recommended when the scraper shows signs of excessive wear, bending, or can no longer clear soil effectively from the blades.

Can I install a new disk blade scraper myself, or do I need a professional?

Many scrapers are designed for straightforward installation, but consulting your equipment manual or a local agricultural supplier can help ensure a proper fit and optimal performance, especially if you encounter unique mounting requirements.

What materials are best for disk blade scrapers?

High-quality, wear-resistant materials such as hardened steel or durable plastic composites are ideal for disk blade scrapers. These materials offer longevity and effective performance in harsh soil conditions.

How do I determine the right scraper for my disk blades?

Consider the type of disk blades (e.g., notched, smooth, or wavy) and your local soil conditions to select a compatible scraper. Consulting with local suppliers can also help in choosing the right option for your specific needs.

What are the benefits of sourcing disk blade scrapers locally in Ipswich?

Local sourcing offers advantages such as quicker access to products, personalized customer support, and expert advice on installation and maintenance. This ensures that farmers can keep their equipment in top shape with minimal downtime.

Why is regular maintenance important for disk blade scrapers?

Regular maintenance, including cleaning and lubrication, prevents rust and buildup on the scrapers, which ensures effective operation. It also extends the lifespan of the scrapers and helps avoid potential equipment downtime.